Creative and productive

Machines to place, position and rotate large components.

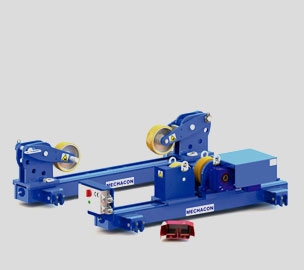

Container rotating devices

The container rotating devices are modified according to the respective application and characterized by their robust and precise construction. The mechanical processing of all contact surfaces particularly reduces the axial movement of the component inserted and considerably increases the effective use in your production. The rollers are available as steel rollers or surfaced with VULKOLLAN or rubber bandages. Bevel or worm gears with adjusted frequency converter are installed as standard. Servo drive technology is used for special applications! Rotational speed and control range are adapted to the corresponding application or customised according to your wishes. We optionally offer the container rotation devices with chassis (manual or motor-driven), trapezoidal spindle for diameter adjustment (manual or motor-driven), remote control, radio remote control or foot switch. In order to prepare an offer, we need the specific component data such as component weight, component diameter, material, sheet thickness, texture and surface, rotational speed and/or welding procedure.

| Rotating device | TR500 – TR10.000 |

|---|---|

| Container diameter | acc. to customer specification |

| Rotational speed of drive rollers | acc. to customer specification |

| Control range, continuously variable | 1:20 – 1:200 |

| Maximum component weight | 500 kg – 10000 kg |

| Diameter adjustment | unilateral with locking pin |

| Rotating device | TR5.000-TR100.000 |

|---|---|

| Container diameter | acc. to customer specification |

| Rotational speed of drive rollers | acc. to customer specification |

| Control range, continuously variable | 1:20 – 1:200 |

| Maximum component weight | 5000 kg – 100000 kg |

| Component diameter adjustment | centric with trapezoidal spindle |

| Diameter adjustment | manual or electromotive |

| Rotating device | RA3.000– RA30.000 |

|---|---|

| Container diameter | acc. to customer specification |

| Rotational speed of drive rollers | acc. to customer specification |

| Control range, continuously variable | 1:20 – 1:200 |

| Maximum component weight | 3.000 kg – 30.000 kg |

| Component diameter adjustment | The roller arm can be swiveled and fixed with a socket pin. |

| Self-aligning rotating device for large Ø ranges | TR3.000 – TR200.000 |

|---|---|

| Container diameter | acc. to customer specification |

| Rotational speed of drive rollers | acc. to customer specification |

| Control range, continuously variable | 1:20 – 1:200 |

| Maximum component weight | 3000 kg – 200000 kg |

| Component diameter adjustment | self-aligning, centric with trapezoidal spindle |

| Diameter adjustment | manual or electromotive |

The illustrated rotating device consisting of drive and rotation unit is manually moveable and can be centrically adjusted in order to adapt the diameter. This device is intended for a maximum component weight of 5,000 kg. Special feature of the turning device is that the rotation unit is equipped with pivoting rollers. This enables the height-adjustment which is necessary for different diameters or conical components. Due to the combination of height and diameter adjustment, the components can be placed and turned in their rotation axis.

The mobile rotating device is used for large cylindrical components which, due to their high net weight and component diameter, have to be welded at the construction side. The device can be centrally divided. In order to weld the component, various rotating devices must be installed according to the number of segments and adjusted to the desired component diameter. The rotating device is equipped with steel rollers which can be adjusted into three axes under load.

The roller table is equipped with one driven and one rotating roller surfaced with PUR bandages. In order to adjust the diameter, it can be centrically aligned by means of locking bolts. The roller table is used for components which require a support as level as possible due to their surface, wall thickness, different component lengths and diameters or due to process-related reasons.